|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All of my materials are placed in a heated

environment to stabilize before machining

|

|

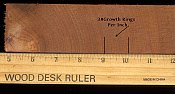

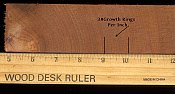

Here are some "end cuts" showing the exceptional

quality of the materials I use for my doors

|

|

one piece has 39 growth rings (or years of growth)

in 1 inch

|

|

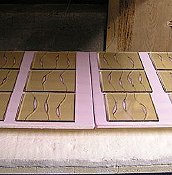

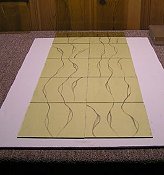

after planing .... the pieces for the sidelight

"settle down" before the final machining and

assembly

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

each mullion is hand fitted

|

|

and bored for Mahogany dowels

|

|

...... then each vertical mullion is hand fitted for

a perfect fit

|

|

at glue up ...... the excess glue is wiped off

........ and we "scrub" the corners with a

toothbrush.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The sidelight remains in clamps for 3-4 days

........ the glue will fully cure ....... and hopefully

.....

|

|

...... last that 100 years of existence I'm

"shooting" for !!

|

|

...... then the machining starts on the Entrance

Door

|

|

The styles are ruff machines and allowed to "settle

down"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here the pieces are being thickness planed

|

|

.... and jointed flat on face ...... from rough

lumber

|

|

Here are the pieces for the door, after planing to

thickness, and about to be cut to width and length

|

|

..... before the slot tennon is machined ........

the ends are coped with a male machined detail

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

here are the mullions after machining

|

|

here .... the fitting begins .... piece by piece

...... and then the pieces are marked for splined

tennons

|

|

...... each mullion is individually cut and

fitted

|

|

..... so they fit like this ......

perfectly!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The average door has at least 14 clamps to achieve

flat and tight joints

|

|

Here the door will cure for 4 days till it can come

out of the clamps

|

|

Here is the entrance door out of clamps

|

|

Here is the door and sidelight

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Then ...... the finishing begins. All of the

chamfered molded edges are hand sanded to a "furniture:"

finish

|

|

......... and sanded

|

|

Here is the panel stock I've picked for the

sidelight panel. It is old growth Redwood ..... 1pc 20"

plank

|

|

I scanned the end grain to show the quality of wood

........ I figured this plank came from a 6ft diameter

tree!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

all of the chamfered stops are made from matching

Mahogany

|

|

The stops then soak in oil

|

|

...... then cure ........ each stop is "soaked" 4

times in my

oil

....... this is the right way

to do it !!

|

|

The mullions are hand sanded, because they are

delicate and need to be treated kindly

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I make all doors slightly oversize then trim them to

actual size and square

|

|

After trimming ....... I sign the door

|

|

...... and back-bevel the leading edge 2deg for easy

of swing

|

|

Here is the sidelight ready to oil

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It is sealed inside and out ..... allowed to cure

3-4 days .... then oiled 3 more times

|

|

Here is the panel stock ....... solid Old Growth

Redwood

|

|

Here they are sanded to a furniture finish

|

|

...... a close up of the sidelight panel ........

such beautiful wood ....... flat sawn so that it will expand

from front to back ....... so side to side

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the first oiling of the Entrance Door ......

3 more to come !!

|

|

Here is the door and sidelight curing in the shop

between oilings

|

|

Here is a preview of the glass before it goes into

the kiln to be fused

|

|

.... and here is the sidelight glass

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The panels are coated with the first of four coats

of varnish oil

|

|

The panels cure for three days between

coats

|

|

Here the sidelight receives its' third coat of

varnish oil

|

|

Here is the door and sidelight curing

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here the custom fused glass is being laid out in the

sidelight

|

|

After the varnish oil has cured, we prep the door

for the dentils and shelf

|

|

the posts are glued down and in prefect

alignment

|

|

Here are the raw posts left to cure for 2-3

days

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The dentil posts will be varnish-oiled 4 times

before I add the shelf

|

|

Here is the dentil shelf, just before

oiling

|

|

The hand fused glass is first "floated" on rubber

blocks

|

|

....... then caulked with a siliconized latex 50

year caulk ... that turns translucently clear when

cured

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the finished sidelight ..... caulked and

curing

|

|

Here is a close up of the 15" wide old growth

Redwood panel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|