|

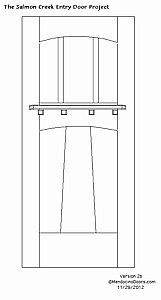

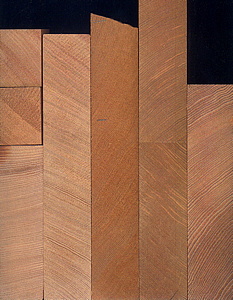

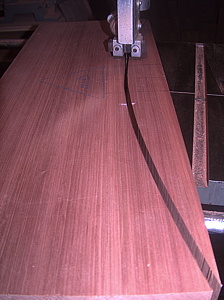

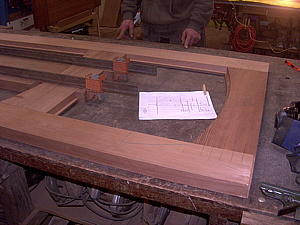

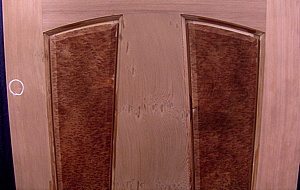

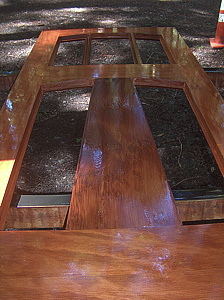

The Salmon Creek Entry Door It is styled after The Otsuchi Craftsman Style Door I made. It is 35-7/8" x 79" x 1-3/4" and is made of Vertical Grain Old Growth Redwood. The mid vertical "taper" is Birds-Eye Redwood and the panels are of elegant Redwood Burl |

|

|||||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

||||

|

|

|

||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

||||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

||||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

Return to Work In Progress |

|||||