|

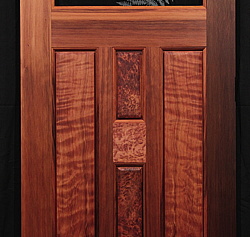

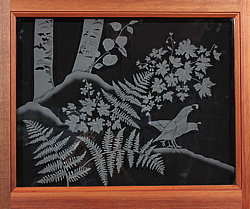

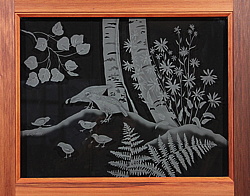

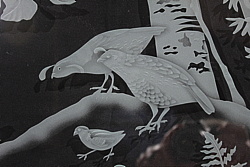

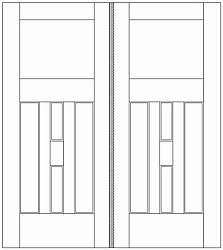

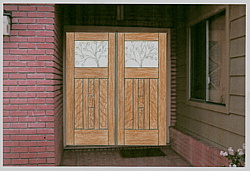

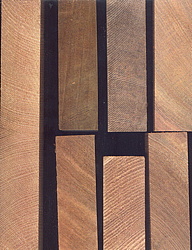

This Entry project is called The Quail Meadows Entry Here is a pair of old growth VG Redwood Doors with Curly and Burl book matched Redwood panels. They are each 36" x 80" x 1-3/4" thick and they have etched & carved seen of Quails in a forest meadow by Cynthia Myers |

|

||||

|

|

||||

|

|

||||

|

|

|

||

|

|

|

|

||

|

Click on Any Image to Enlarge |

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

The glass is Etched and Carved by Cynthia Myers |

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

||||

|

|

|||

|

|

|

|||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

||||

|

|

||||

|

Return to Door Gallery RETURN to Doors in Progress |

||||