|

|

|

|

|

|

|

|

|

|

|

|

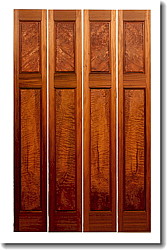

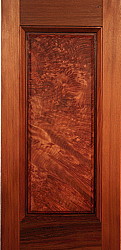

Here are the completed doors

|

|

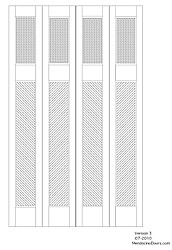

Here is the third and final drawing

|

|

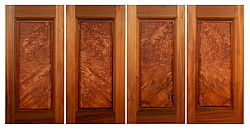

Here is another view of the completed

doors.

|

|

|

Click on ANY

Image to Enlarge

|

|

|

|

|

|

|

|

|

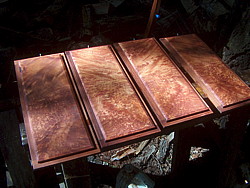

Here are the upper panels. They are book matched

Redwood burl.

|

|

The lower panels are satin quilted curly Redwood.

They are also book matched.

|

|

Heres a view of the backs of the doors. The back

panels are extremely tight VG Redwood.

|

|

|

|

|

|

|

|

|

|

|

|

|

Heres another view of an upper burl panel.

|

|

Heres a close up of a lower panel.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heres a close-up of a panel back.

|

|

and here is a view of the back of an upper

panel.

|

|

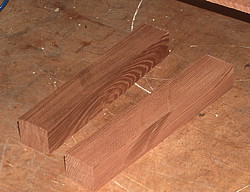

Heres some end cuts of the VG Redwood used to make

the doors. There are 40-45 growth rings per inch.

|

|

|

|

|

|

|

|

|

Below is the provenance of the creation of these

doors

|

|

|

|

|

|

|

|

|

|

|

|

|

and all of the vertical stiles came from the same

wood.

|

|

Here is the wood ready to be machined.

|

|

Here is the wood after being planed.

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are the doors glued up,where they will remain

for 72 hours.

|

|

|

|

The first step after clamps,is to dimensional sand

each door.

|

|

|

|

|

|

|

|

|

|

|

|

|

Now they are ready for hand finishing

|

|

Hand sanding the detail on each door.

|

|

Here are the panel blanks being edged

glued.

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are upper panels blanks being edge

glued.

|

|

Here we surface the edging and the ends.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are the Redwood ends.

|

|

|

|

All of the panels are end glued.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We then vacuum press bookmatched thick

veneers.

|

|

After 3 days in the press we start to finish each

panel.

|

|

|

|

|

|

|

|

|

|

|

|

|

Here we hand sand each bevel.

|

|

and machine sand each rebate.

|

|

After 2 days of work the panels are ready to oil

with 4 coats of our varnish oil.

|

|

|

|

|

|

|

|

|

|

|

|

|

and we hand sand each door detail to a furniture

finish.

|

|

and sand all surfaces to a highly finished

surface.

|

|

Here is the first of 4 oilings.

|

|

|

|

|

|

|

|

|

|

|

|

|

Here Zoey mortise's the door for hinges.

|

|

We used 3-1/2 inch bronze hinges for long lasting

utility.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Deja vu

|

|

Here we signed each door proudly.

|

|

The panels are touched up for oiling.

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are the lower panels just before

oiling.

|

|

See how they come alive !

|

|

Amazing!

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are upper panels ready to be oiled.

|

|

Look at that shine.

|

|

Here are the backs of the upper panels.

|

|

|

|

|

|

|

|

|

|

|

|

coat number 3

|

|

Such gorgeous wood.

|

|

The doors receive there final coat.

|

|

|

|

|

|

|

|

|

|

|

|

Looking up from oiling the doors..... this is what

you see. We truly live in a Redwood forest.

|

|

Here are the panels ready to be installed in the

doors.

|

|

Here are the doors ready for the panels.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Each stop is hand fitted and cut.

|

|

and fitted to perfection.

|

|

|

|

|

|

|

|

|

|

|

|

and the process continues.

|

|

Here are the completed doors!

|

|

Each panel floats independently inside each

frame.

|

|

|

|

|

|

|

|

ALL of our Old Growth Redwood comes from salvaged

wood and 100 year old "buckskins" that have laid out in the

forest floor for 70 to 100 years. Since Redwood heartwood

does not rot or remains unharmed by insects ....... then

small independent sawyers haul out these logs and saw them

into lumber ........ and we buy the best of the best

!!

|

|

|

|

The finished product.

|

|

|

|

The front view of the same panel.

|

|

|

|

|

|

|

|

|

|

|

|

|