|

|

|

|

|

|

|

|

|

|

|

|

|

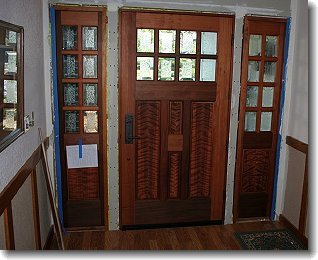

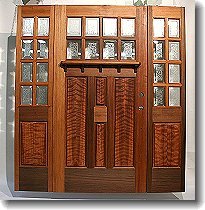

Here is the Inglenook installed on its' new home

|

|

.... and another view

|

|

. and yet another view of the installed entry

|

|

|

|

|

|

|

|

|

|

|

|

|

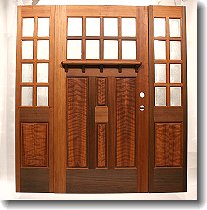

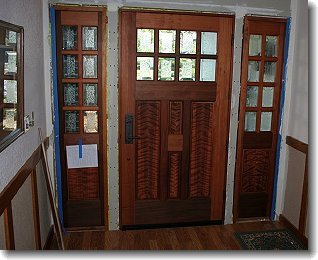

Here is the completed Entry and Sidelights

|

|

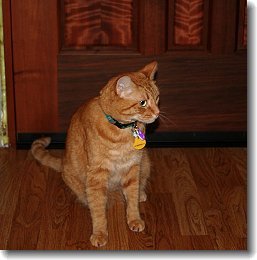

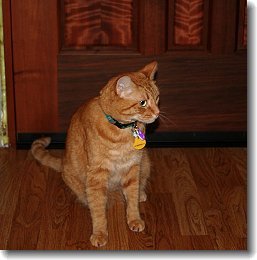

......... and yet another critic ... with approval

|

|

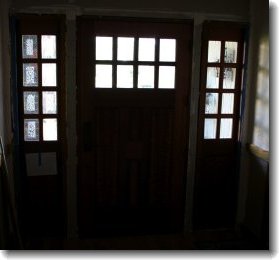

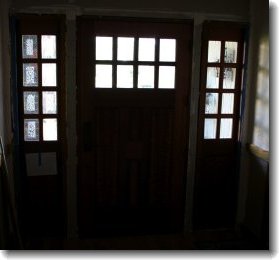

Here is the Entry with no backlight

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the completed Inglenook Entry Door

|

|

..... a close-up of the book matched curly Redwood

panels

|

|

....... another view !

|

|

|

|

|

|

|

|

|

|

|

|

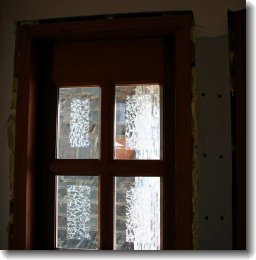

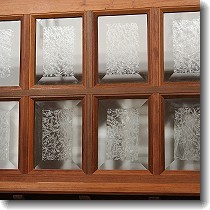

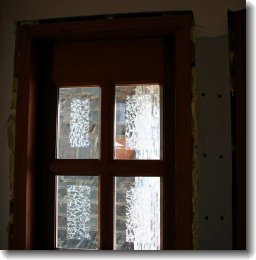

Here you see beveled glue chip glass

they are tempered and insulated units

|

|

Here are the sidelights which go into separate jambs

on each side of the Entry door

|

|

The close up of glass with no back light

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The upper half of the sidelights

|

|

Here are the book matched curly Redwood panels in

the sidelights

|

|

....... a closer look ...... beautiful !!

|

|

|

|

|

|

|

|

|

|

|

|

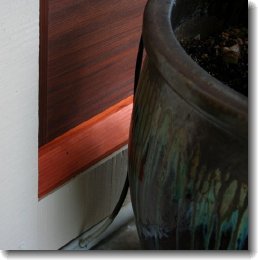

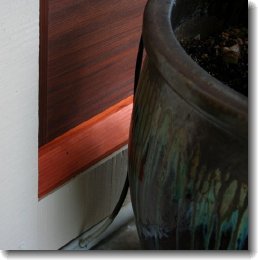

Here is a close-up of the installed door

|

|

... from the other side

|

|

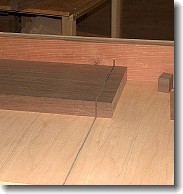

Trimming the sidelights

|

|

|

|

|

|

|

|

|

|

|

|

Here the old entry was removed

|

|

Here the opening is framed with a header and

posts

|

|

Ready for the door and sidelights

|

|

|

|

|

|

|

|

|

|

|

|

a view ( without flash) from the inside

|

|

the sheetrock is installed

|

|

the beveled glue-chip glass ........ from the

inside

|

|

|

Return

To Door Gallery

|

|

|

|

|

Here is the "history"

of how The Inglenook

was constructed

|

|

|

|

|

|

|

|

|

|

Please notice the density of the growth rings of

this Old Growth Redwood

|

|

I pre cure all of my wood depending on which region

of the Country it will "live"

|

|

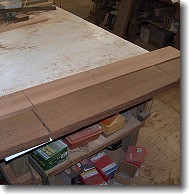

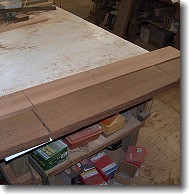

Here the wood is rough cut and joined flat, then

planed to thickness

|

|

|

|

|

|

|

|

|

|

|

|

then each piece s ripped to dimension

|

|

and the horizontal piece are cut out of the same

board ..... because that's the right way to do it !

|

|

then each piece is cut to length

|

|

|

|

|

|

|

|

|

|

|

|

the pieces are coped with the female end of the

shaped detail

|

|

then run through another shaper for the molded

detail .. the center rails and mullions are doweled with

Mahogany dowels that we make in the shop

|

|

Here is the door being glued up

|

|

|

|

|

|

|

|

|

|

|

|

Here is the door .. glued up and cleaned ....... and

will now cure for at least 72 hrs

|

|

...... on to the sidelights

|

|

here is he Inglenook .. fresh out of clamps

|

|

|

|

|

|

|

|

|

|

|

|

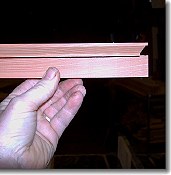

Each vertical mullion is fitted for any slight

variation if the fir

|

|

If it fits tight when "dry" it will glue up right

!!

|

|

The I shape the molded edge to each mullion .....

here is one

|

|

|

|

|

|

|

|

|

|

|

|

and here they are ....... out of clamps

|

|

here's Jasons daughter ....... out on a Saturday

....... to help dad glue up the panel stock

|

|

........ and drill some dowel holes ..... perfect

hieght !!

|

|

|

|

|

|

|

|

|

|

|

|

Here is a piece of the log that I resawn the figured

Redwood "thick" veneer

|

|

Each piece of curly Redwood is kept in a perfect

bookmatch

|

|

..... and is glue together edge to edge

|

|

|

|

|

|

|

|

|

|

|

|

The pieces stay in the press for 3 days under a

vacuum of 25

|

|

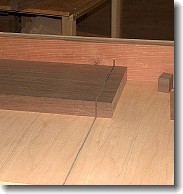

Here the sidelights are trimmed to actual

size

|

|

I make each door 1/2 inch oversize the cut and joint

it to the exact dimension

|

|

|

|

|

|

|

|

|

|

|

|

Here is the beveled glue-chip glass. It is also

tempered and thermal

|

|

Here the sidelights are hand sanded then machine

sanded on the faces

|

|

Here I have "signed" the door and I am mortising for

the 4" ball-bearing hinges

|

|

|

|

|

|

|

|

|

|

|

|

|

And the oiling begins. Here is the first of 4

coats

|

|

Each coat of varnish oil will "cure" for 3 days,

before the next is applied

|

|

Here the hand sanding is completed on the entrance

door

|

|

|

|

|

|

|

|

|

|

|

|

|

After spraying both sides .... we allow it to absorb

to 1-2 hrs before wiping off the excess varnish oil

|

|

and here the door will cure for 3 days before the

next coat of oil

|

|

We soak the Redwood stops in oil

|

|

|

|

|

|

|

|

|

|

|

|

Here I am machining the Curly Redwood

panels

|

|

Here are the panels waiting to be sanded

|

|

We even hand sand much of the details of each

panel

|

|

|

|

|

|

|

|

|

|

|

|

another view of the panels

|

|

these pieces of Curly Redwood are all book matches

...... all from the same tree

|

|

The panels cure for 3 days till the next coat of

varnish oil

|

|

|

|

|

|

|

|

|

|

|

|

Here the pieces are "rough cut" for the wood

stops

|

|

....... then each piece is hand marked and cut to

fit ..... 64 miters just for these 8 glass lights

!!

|

|

Then the wood stops are marked and cut for the

floating wood panels

|

|

|

|

|

|

|

|

|

|

|

|

Then all of he excess caulk is removed and allowed

to cure for 72 hrs

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Return

To Gallery

|

|

|