|

|

|

|

|

the rough Mahogany is cut out and allowed to "settle

down" for a couple of weeks.

|

all of the rough lumber is then made straight on a

wide face joiner

|

all of the pierces are the surfaced and thickness

planed to 1-3/4"

|

the pieces are then sized to width and cut to my

"fitting" length

|

|

|

|

|

|

|

|

Click on

Images

|

to Enlarge

|

|

|

|

|

|

|

|

|

|

|

|

EACH piece is the cut and fit ...... piece by piece

....... to insure exceptional joinery

|

The final "dry" fit allows to make sure every thing

is ready for assembly

|

The door is then glued and all of the excess is then

wiped and rinsed off of the wood.

|

Here the door is glued up, cleaned off, and is left

in clamps for at least 3 days .......... to cure

properly.

|

|

|

|

|

|

|

|

|

|

|

The the door is finish sanded

|

All of the molded edges are hand sanded to insure a

furniture grade finish

|

The hinge pockets are mortised and I "sign" my

work

|

After the door is finish sanded it is oiled with my

varnish oil

|

|

|

|

|

|

|

|

|

|

|

|

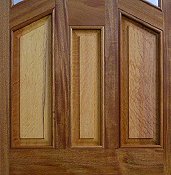

Here is a close-up of the oiling and the beautiful

Mahogany

|

Here is the door "curing" between coats of of

oil

|

Each stop is cut and fitted for the beveled thermal

glass

|

|

|

|

|

|

|

|

Click on

Images

|

to Enlarge

|

|

|

|

|

|

|

|

|

|

|

|

Here is the panel stock of Striated Fir

|

Now I start shaping the Striated Fir raised

panels

|

The completed panels after shaping

|

Then each panel is sanded before oiling

|

|

|

|

|

|

|

|

|

|

|

The panels are all oiled with 4 coats of oil before

being installed into the door

|

Here is a finished Striated Fir Panel

|

All of the stops are soaked in varnish oil before

cutting and fitting

|

Here the stops are being cut and fitted for the

panels

|

|

|

|

|

|

|

|

Click on

Images

|

to Enlarge

|

|

|

|

|

|

|

Most of our exceptional fabricated glass products have

been constructed by Thermal Sun Glass of Santa Rosa,

CA

|

|

|

|

|

|

Here is the finished door laying on the

bench

|

Here is a close up of the amazing

Striated Fir

|

|

|

|

|

|

|

|

|

|

|

|

Here is the completed door

|

Here are the Striated Fir Raised Panels

|

More panels

|

Another picture of the door

|

|

|

|

|

|

|

|

|

|

|