|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the front of the future home of The

Fullington

|

|

.... and a view of the rear

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

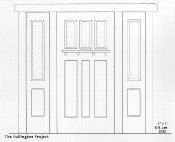

Here is the clients sketch

|

|

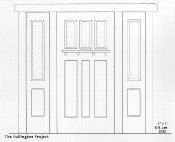

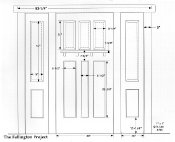

Here is a scale drawing with some changes

|

|

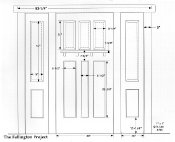

and here is the dimensional layout

|

|

and here is a framing schedule for the

contractor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the rough genuine Mahogany lumber is

selected

|

|

some of it comes from some rare large

planks

|

|

........ very large Mahogany planks

22" plus !!

|

|

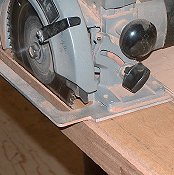

.... it's time to sharpen up to shear

(not tear) this fine

mahogany to size

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I sharpen my joiner and planer knives ........ and

it's done right !!

|

|

here are the "rough" pieces cut to a manageable

size

|

|

....... then all the wood is joined on face to make

it straight and flat

|

|

......... and then the pieces are thickness planed

.........

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

...... from 2"+ down to 1-3/4" thick

|

|

the pieces are will then be cut to width and

length

|

|

..... then they are laid out for color and matching

before machining

|

|

Here is one of the two sidelights

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the parts are then coped on a shaper

|

|

and then the edges are machined with the "sticking"

which is a chamfered step bevel of my design

|

|

here are some of the pieces after machining. Notice

the beautiful vertical "ribbon" grain

|

|

The vertical pieces are then individually fit to

length ....... it takes about and hour to fit the pieces

properly ....... before it's ready for glue up.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the first sidelight fitted and glued up

......

|

|

.......... and the any excess glue is removed with

water and detailing

|

|

Here are the sidelights in clamps

|

|

........ and the door in clamps ... where they will

stay for 3-4 days while the glue cures

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the Entrance Door out of clamps

|

|

.... and here are the sidelights

|

|

Here are the book matched panels for the

door

|

|

here my sander, we call "speedy"

(because it is so slow) does most of

the sanding

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the outer panels are straight grain Redwood and the

center is bookmatched Redwood curly grain

|

|

here are the bookmatched curly redwood panels for

the sidelights. I have wet them with water to show the

grain

|

|

The panels will soon be finish sanded and then

oiled

|

|

All of the details of the edges are also finish

sanded

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

... and here we start the hand sanding of all the

molded detail

|

|

and the sidelights

|

|

Then each style and rail is inspected and hand

finished

|

|

The entire sidelight and door will be sanded to 220

grit finish

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here we detail even the edges

|

|

The door receives its' final sanding

|

|

Each door is made 1/2" oversize and then perfectly

squared and .......

|

|

...... cut to size on top and bottom

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here I mortise for the hinges one at a time .....

and always

|

|

.......... have a perfect fit and then I can "sign"

the door ....... because I'm proud of it !!

|

|

Here are the jambs for the sidelights and

door

|

|

Then we give the door its' first coat of varnish

oil

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

........... panels too

|

|

The varnish oil is allowed to soak in for 45 mins to

and hour

|

|

Here the door will cure for 4 days ...

|

|

....... before I attach the dentils and shelf. I

want it sealed under the dentil shelf

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is one of the two sidelights curing for at

least 3 days before re-oiling

|

|

Here are the panels curing for 3 days before

re-oiling

|

|

The dentil posts will be attached with 1" Mahogany

posts

|

|

I make my own dowels ........ cause no one else

does!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

They will be set in with glue and an old style

technique of wedged tenons

|

|

Then clamped for 36 hrs

|

|

and a little sanding and we're ready for oiling the

entire door for 3 more coats of varnish oil

|

|

a quick check on the fit of the shelf

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and then I mortised for the square Rosewood

pins

|

|

I oiled the shelf separately ......... so that all

sides of the shelf get sealed

|

|

Here we mortise the jamb for the 4 hinges

|

|

Then all of the jambs are finish sanded

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

double check the fit

|

|

and oil them with 3 coats of varnish oil ......

Notice the beautiful ribbon grain

|

|

All of the stops are SOAKED

in our varnish oil ........ before they are

fitted

|

|

here they drain and then are wiped

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CLICK HERE

to see the custom shipping case

|

|

The last coat of oil

|

|

...... and it will have to cure for 3-4 days before

we can start adding all the "pieces"

|

|

Here are the beveled, insulated, and tempered units

.......... each are dual sealed for longevity

|

|

|

|

|

|

|

|

|

|