|

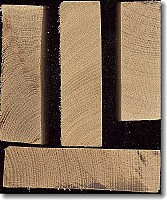

They are 36" x 94 " They are quarter sawn Eastern White Oak with tempered insulated glass |

|

|

||

|

|

after 3 to 4 coats of varnish oil |

||

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of the White Oak |

|

|

|||

|

|

|||

|

|

|||

|

|

|

|

|

and all vertical !! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

I sign my work |

|

|

|

|

|

|

WOW !! |

|

|

|

|

|||

|

|

|||

|

|

|||