|

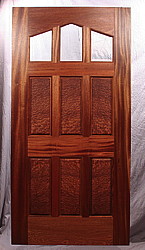

The Cliffs of Cork Entry Door It is 42" x 84" x 1-3/4" It is made of Ribbon Grain Mahogany with Book Matched Redwood Burl panels and beveled, insulated glass |

|

Here is the Completed Door |

Each panel (on both sides) is a book-match |

Another view of this beautiful door |

||

|

Click on ANY Image to Enlarge |

||||

|

Here is the drawing of the project before I started ..... "how'd I do?" |

a close-up of the book matched panels |

and closer ..... |

||

|

see the chatoyancy ..... |

and closer look with the beautiful ribbon grain Mahogany |

and closer yet !! |

||

|

|

||||

|

All of the glass is insulated and tempered ...... the out facing glass is beveled |

hard to photograph |

such lovely wood |

||

|

|

||||

|

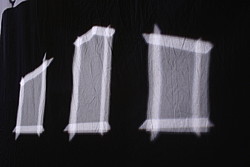

a cool reflection on the backdrop |

what a marvelous job of fitting miters |

here is a view of the bevel |

||

|

|

||||

|

Here is the history and

photographic provenance of |

||||

|

Click on ANY Image to Enlarge |

||||

|

The Styles and mid-rails came from on piece of VG Ribbon grain Mahogany |

The top rail and bottom rail came from the same plank of Mahogany |

|||

|

|

||||

|

The grain was so figured I could not machine it with conventional tools |

....... it had to be dimensionally sanded |

The rough "blank" |

||

|

|

||||

|

laying out the top rail |

careful |

it is easier to follow the line on the tape rather then on wood |

||

|

Click on ANY Image to Enlarge |

||||

|

got it ! |

Then I hand smooth the saw kerf with Euro files |

and other tools |

||

|

|

||||

|

here the top rail is machined .... |

Laying out the equidistant rails for the splined tennons |

Then I calculated the mid-vertical rails |

||

|

|

||||

|

and started machining and fitting |

I was so exact that I made equidistant spacers to insure the process |

Ta-Da ! |

||

|

|

||||

|

Here we glue 'er up |

with 22 clamps !! |

Then we clean all of the glue |

||

|

|

||||

|

and this monster stayed in clamps for 72+ hours |

fresh out of clamps |

and the sanding begins |

||

|

Click on ANY Image to Enlarge |

||||

|

Trimming to length |

and every molded edge is hand sanded 2-3 time ...... to furniture grade |

here is the Redwood Burl we used for the panels in this door |

||

|

|

||||

|

what a beauty |

a view with a dab of water ...... electric !! |

here are the bookmatched this veneers which are 5/16" thick |

||

|

|

||||

|

Here is the panel sub-core being machined |

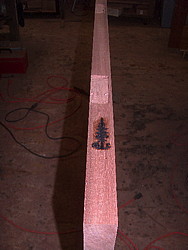

Here I mortised for the hinges |

and ...... signed it ! |

||

|

|

||||

|

here are the veneers, waiting to be covered in glue |

then wrapped up tight |

then they go into a vacuum press and stay under pressure for 3-4 days till the waterproof glue cures |

||

|

|

||||

|

Then they are sanded to dimension |

They are about 1-5/8" thick |

and I start to machine them |

||

|

|

||||

|

I shape and machine the panels |

a closer look |

each panel is machined ......... |

||

|

|

||||

|

and hand sanded to a furniture finish |

then the fun ........ of oiling ... WOW !! |

here is the raw door before varnish oil |

||

|

|

||||

|

and then it comes to life |

have a look !! |

Each coat (of 4) cures at least 3 days between coats |

||

|

|

||||

|

here we finish the jambs |

then oil them |

The panels are sorted and matched |

||

|

|

||||

|

then put in place |

the panels "float" and are suspended with neoprene balls |

and EACH stop is cut and hand fitted |

||

|

|

||||

|

they are caulked in place with siliconized latex |

I use this ..... because it really adhere to wood |

here is the glass units |

||

|

|

||||

|

then each stop is hand cut |

and fitted |

it is a lot of effort ... to do it right

...... |

||

|

|

||||

|

the glass also floats |

caulked in place |

....... and this baby is done !! |

||