|

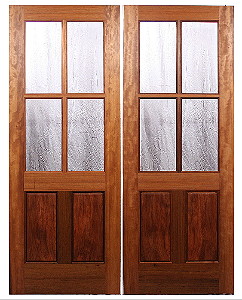

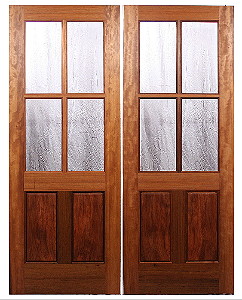

The Chapel Hill Entry Doors Each door is 36" wide x 94" tall. They are Redwood with Redwood panels and clear insulated glass. |

|

||||

|

More completed pictures to come soon !! |

||||

|

Click on Any Image to Enlarge |

||||

|

|

||||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

||||

|

The Chapel Hill Entry Doors Each door is 36" wide x 94" tall. They are Redwood with Redwood panels and clear insulated glass. |

|

||||

|

More completed pictures to come soon !! |

||||

|

Click on Any Image to Enlarge |

||||

|

|

||||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

||||