|

|

|

|

|

|

|

|

|

|

|

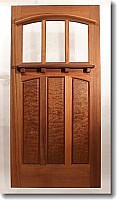

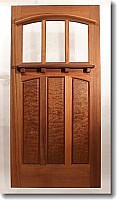

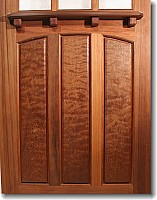

Here is the completed door

|

|

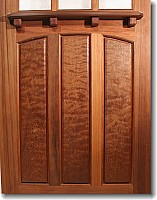

Here is a close-up of the upper half of

The Carpinteria

|

|

Here is another view of The

Carpinteria

|

|

|

|

|

|

|

|

|

|

|

|

The panels are bookmatched flat sawn curly

Old Growth redwood

|

|

Here is a close up of the Redwood

Panels

Nice ..... huh !!

|

|

The Eyebrow if bent laminated

Redwood

|

|

|

|

|

|

|

|

|

|

|

|

and the eyebrow "floats "off the door on

Mahogany pins

|

|

The dentil shelf is attached with stainless

steel screws and capped with beautiful pins of Pao

Brasil

|

|

The glass is tempered and insulated art

glass called Seedy Reamy

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

....... and here are the Boys !

|

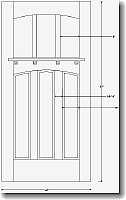

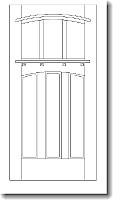

Here is a view of the drawing on the

front of the house

|

Here are the dimensions

|

Here is a drawing of The Carpinteria

|

|

|

|

|

|

|

Here is the

History

of how this door was constructed

|

|

|

|

|

|

|

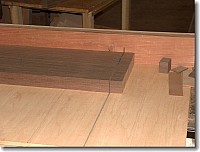

Here is the "rough stock" that will make this

door

|

Every piece is cut oversized and the joined straight

and then surfaced to thickness

|

Then cut to exact length

|

Here are some more pictures of the rough

stock

|

|

|

|

|

|

|

|

|

|

|

Here I am cutting the template for the arched top

and mid rail

|

...... and here I am dimension sanding the top and

mid rail to 1-3/4" thick

|

Then I transfer the arc to the pieces

|

Drill the top piece for the mullions and pre drill

and fill the holes with dowels ...... cool trick

|

|

|

|

|

|

|

|

|

|

Then I cut the arcs

|

and you can see the dowels that are left and after

planing they will accept machining

|

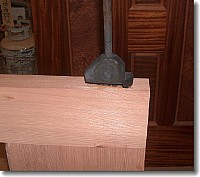

The I "smooth" the arc with a 100 year old plane,

called a compass plane because the sole is

adjustable

|

Then comes the hand sanding

|

|

|

|

|

|

|

|

|

|

Then I fit each piece ... one by one

|

... know this ..... a perfect joint does not allow

the "union" of the woods to fail

|

and I spend a lot of time making sure that each

piece fits .... "just right"

|

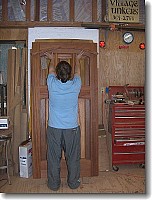

Then we glued up The Carpinteria and remove all the

excess glue we can

|

|

|

|

|

|

|

|

|

|

... and yes ....... scrub the corners with a

toothbrush and clean water ..... then blow off the water

with compressed air

|

Here the door will cure for at leas 3 days

|

And then we're ready to sand the door. Here Jason is

doing all of the scraping first

|

The we start machine sanding the door all the way

down to 220 grit

|

|

|

|

|

|

|

|

|

|

And of course ....... hand sand all of the molded

edging .... inch by inch

|

Then I heat up my signature

|

and place it of the hinge edge

|

This means I (we are) am proud enough to tell folks

who made this piece of fine woodworking

|

|

|

|

|

|

|

|

|

|

Not forgetting to sand the edges

|

and "back bevel" the opening edge

|

Here is the door ready to be sealed and

oiled

|

Even the inside of the panels and glass gets 4 coats

of our varnish-oil

|

|

|

|

|

|

|

|

|

|

|

... yes 4 coats and we wait at least 3-4 days

between coats

|

Here I made templates to mail of to ThermalSun

...... who will make the insulated and tempered glass

units

|

Here are the panel blanks with the Redwood edging

being applied

|

and here are the panel blanks after having the

figured Redwood panels glued on

|

|

|

|

|

|

|

|

|

|

The panels are being sanded on my wide belt sander

....... they are curly Redwood and bookmatched to each

other

|

Here I cut the arc in the tops of the

panels

|

and the cut the rebates

|

Here are all 3 panels

|

|

|

|

|

|

|

|

|

|

Last step is to chamfer the panel edge ...... just

to add another dimension

|

Here are the panels ready to be hand sanded

|

and here they are with their first of 4 coats of

oil.

|

There are the pieces that will make up the bent

laminated eyebrow

|

|

|

|

|

|

|

|

|

|

They are sanded to dimension

|

The clued in this form and allowed o cure for 4

days

|

Here is the blank out of the press

|

Then cut to width and sanded ..... and

sanded

|

|

|

|

|

|

|

|

|

|

After machining we have a "sneak" preview as ti its'

proportions ..... Great !!

|

Here are the panels .... the dentil shelf .... and

the eyebrow ..... all be saturated with our varnish

oil.

|

.......whadaythink ?? ..... not bad !!

|

Here the glass is being caulked with a special caulk

(that turns clear) and will be

covered with curved steam bent stops

|

|

|

|

|

|

|

|

|

|

Here are all of the stops laid out and

precut

|

Then we caulk the floating panels and clean up any

squeeze out

|

Here the door will lay flat while the caulk cures

for 3 or 4 days

|

... so I start to layout the eyebrow

|

|

|

|

|

|

|

|

|

|

The redwood eyebrow will be attached with Genuine

mahogany dowels that UI made in shop

|

Then I layout the dentil shelf placement

|

and the dentil posts

|

Then glue the dentil post to the door

|

|

|

|

|

|

|

|

|

|

|

and glue on the eyebrow

|

The dentil shelf is attached with stainless steel

screws but I cap them with wood pins ..... here I am

chiseling the diamond

|

These pins are made from a wonderful reddish wood

called Pao Brasil

|

Here is a close-up of the attached eyebrow

|

|

|

|

|

|

|

|

|

|

|

and here is the door complete

|

and ........... here is the door complete!!

|

These are the same at the top of the page

|

........ enjoy !! ........

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|