|

|

|

|

|

|

|

|

|

|

|

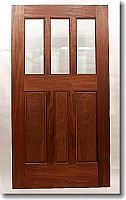

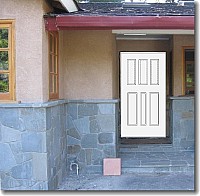

Here is the completed

Calpella Entry

Door

|

|

|

|

|

|

|

|

|

|

|

The is the original drawing

This was 1 of 4 versions I drew

|

|

Here I overlaid the drawing on the

entry

|

|

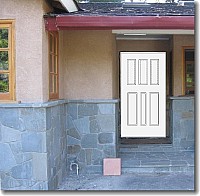

Here I overlaid the door on the

entry

|

|

|

|

Click on Any

Image to Enlarge

|

|

|

|

|

|

|

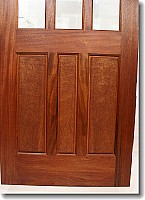

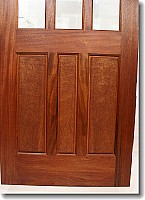

Here is a close-up of the beautiful "Oyster Shell"

Mahogany panels

|

...... another view of the panels.

They are raised on both sides

|

Notice the fine grain Mahogany

|

These units are beveled glass units which are

tempered and insulated

|

|

|

|

|

|

|

|

|

|

Here is the history

of the construction of this entry

|

|

|

|

|

|

|

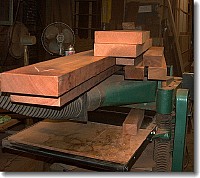

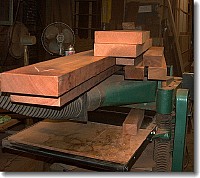

Here is the rough 2" lumber

|

All pieces are joined straight and then....

|

...... they are thickness planes

|

Here the pieces are "roughed out"

|

|

|

|

|

|

|

|

|

|

And then each piece is cut to its' exact length and

"dry fit" ....... it's a long process but the finished door

makes it all worth it

|

Here is the door, just glued up and in clamps and

the excess glue is wash off ..... over and over

|

........ and over

Think we used enough clamps .... our doors will endure the

elements and the tests of time

|

All of the corners are scrubbed with a

toothbrush

|

|

|

|

|

|

|

|

|

and the more clean water and scrubbed again ......

smile !!

|

Here the door rested in clamps for at least 3

days

|

and the a check for flatness and the sanding

begins

|

I join and backbevel the edges

|

|

|

|

|

|

|

|

|

|

and the "fire up" by branding iron

|

and we sign each door ..... with pride

|

here I am mortising for the hinges

|

and here ya go !! 4" ball bearing hinges

|

|

|

|

|

|

|

|

|

|

Here is the door receiving the first coat of of

varnish-oil

|

and the door will receive 4 coats to protect it for

a long time

|

Here are the panel "blanks". They are 1-3/8"

thick

|

and here are the bookmatched oyster shell Genuine

Mahogany

|

|

|

|

|

|

|

|

|

|

|

Here they are ready for oil

|

and here they are being oiled.

|

The door cures for at least 3-4 days between coats

of oil. It needs time to cure.

|

Here is the door jamb under construction

|

|

|

|

|

|

|

|

|

|

Here are the jambs after oiling

|

Here is a glass unit. It is beveled and

insulated

|

Here are all the "pieces" in their new home

|

The panels "float" in their opening so they can

expand and contract

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here you can see how all the panels

float.

We then cut and fit each Mahogany stop

|

|

.... and the seal under the stops with a

special siliconized caulk which turns clear when it

cures.

|

|

The excess calk is removed after it has

squeezed out.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|