|

|

|

|

|

|

|

|

All the final calculations are double checked

....... and the process begins

|

|

Here is one of the boards I pulled for these

doors

|

|

This tree was Chopped

Down by an ax over 85 years ago

|

|

Here are all the rough lumber boards that will make

the two doors

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

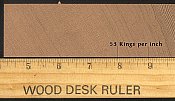

Here are some end cuts that I scanned to show the

quality of Redwood used in these doors

|

|

One piece had over 50 growth ring to 1 inch of

growth

|

|

Here are all the rough cut planks that will be

used

|

|

Each board is jointed flat and straight

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

......... The plane to the thickness of 1-3/$ of an

inch

|

|

then the finished boards are ripped to

width

|

|

......... and then cut to length

|

|

Here are all of the pieces ....... finished cut

...... ready for mortising and machining

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I then start to fit the pieces ....... each piece is

cut to fit and just not "batched"

|

|

Here I shape the ends with a cope cut on the

shaper

|

|

.... and then the "sticking" is shaped

|

|

The pieces are "dry" fit and labeled for

glue-up

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The pieces are pre-glued and the coated with glue

again

|

|

All excess glue is wiped off

|

|

and all corners are cleaned with a

toothbrush

|

|

Here are the two upper halves ....... and they will

remain in clamps for 72 hrs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here they rest .... out of clamps

|

|

The beveled molded edge is then hand sanded

|

|

Here the lower parts .... dry fitted

|

|

... and then glued up

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

... here the bottom half is clamped in all

directions

|

|

Here they will cure for the next 3 days

|

|

Here are the lower halves ...... out of

clamps

|

|

since I make the slightly oversize ....... I then

cut them to actual size

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here I am trimming the upper half

|

|

Here are the parts for the two Dutch doors

|

|

The the hand sanding begins on all the molded

edges

|

|

The hand work .... includes the hand finishing of

the Dutch half-lap

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

They are then finished and prepped for oil

|

|

Here we start the 1st of 4 coats of

varnish-oil

|

|

......... a finished half

|

|

here it will cure for at least 3 days before the

next coat

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the final hand sanding on the upper halves

|

|

Here is the curly Redwood for the panels

|

|

It is old growth ...... and each piece is a book

match ........ and all ..... are bookmatched to each

other

|

|

Here they are glues up and left to rest for 3

days

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applying one of four coats for my Varnish-Oil

to the upper half of the

Dutch doors

|

|

wiping off the excess oil

|

|

they will then cure for 3-4 days before the next

oiling !!

|

|

............ another view ......... such beautiful

wood

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

here I rabbit the 1-1/2" jambs and then notch the

head of the jamb for the top piece

|

|

The solid Redwood jambs

|

|

here we sand the rabbits ...... and then I'll notch

them for weatherstripping

|

|

all of the stops are

SOAKED

........ 4 times in our oil

......... our doors are sealed from The Inside

Out.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are some Mahogany and Redwood stops curing

between soakings !!

|

|

We are using figured Curly bookmatched Redwood for

the panels

|

|

they are resawn ..... bookmatched ...... and then

laminated to solid Redwood panels stock ......... here is my

vacuum press where the panels will remain under pressure for

72 hrs

|

|

Here are the panel "blanks" fresh out of the

press

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here the panels are being machined

|

|

... then they are machine and hand sanded

|

|

Here the receive their first (of four) coats of

varnish oil ...... here you see before and after

|

|

a panel with oil ...... electric

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here the doors are mortised for hinges and then

"signed"

|

|

Here is the placement of the Dutch slide

hardware

|

|

Here I am boring for the knob set

|

|

... and here I'm squaring up the strike plate

mortise

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here the jambs are being sanded before

oiling

|

|

The panels cure for 3 days between coats of varnish

oil

|

|

Here is the set of Dutch Doors with their 4 coat of

varnish oil

|

|

After the doors are bored for the lock sets ..... I

oil the "cut" three times .... that's the right way

!!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The insulated-tempered units are set in place and

the material for the stops is cut oversize and then

individually mitered

|

|

The glass is set on rubber blocks and caulked with a

50 year siliconized caulk which turns clear upon

curing

|

|

The "squeeze out" is cleaned up and the stops are

set with stainless steel fasteners

|

|

The bookmatched curly Redwood panels actually

"float" in their frame

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

They are suspended with neoprene spacers which allow

them to expand and contract with the weather

|

|

The panels are then caulked with a 50 year

siliconized caulk which turns clear upon curing

|

|

The "squeeze out" is cleaned up and the stops are

attached with stainless steel fasteners

|

|

|

|

|

|

|

|

|

|

|