|

|

|

|

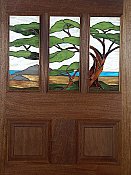

The completed Cypress Door

|

Here it is on its' new home !!

|

another view of the completed Cypress Door

|

|

|

|

|

|

|

Click on Images to

Enlarge

|

|

|

|

|

|

|

This glass was designed and

crafted in collaboration

with Fagerskog Glass of Fort Bragg

|

|

|

Here is a sunlit view of the beautiful

glass

|

|

Here is a backlit view of the glass

|

|

|

|

|

|

|

|

|

The panels are old growth Redwood

|

|

Here is another closeup of the panels and

glass

|

|

|

|

|

|

|

|

|

|

|

A drawing of the door overlaid on a picture of the

entry

|

A proposal for the stained glass

|

Here the wood settles down before machining

|

Here the machined pieces are dry fitted before glue

up ...... ahhh ..... perfect !!

|

|

|

Click on Any

|

Image to

Enlarge

|

|

|

|

|

|

|

|

|

|

|

|

Here the door is glued up and cures for

72hrs

|

Here is the door out of clamps

..... ready to be sanded and trimmed

|

Signed !!

|

Mortised for hinges and my brand.

|

|

|

|

|

|

|

|

|

|

The door framework is finish sanded and receiving

its' first coat of oil

|

Here is the door after 1 coat of oil

...... three more to come !!

|

Oiling the panels

|

Here are the panels after 1 coat of oil

...... three more to come !!

|

|

|

|

|

|

|

|

Click on Any

|

Image to

Enlarge

|

|

|

|

|

|

|

|

|

|

|

|

The panels and door are oiled separately with 4 coats of

varnish oil

|

The panel actually float and each stop is hand

fitted to the opening

|

The panels are bedded and caulked with s siliconized

caulking which turns clear when cured.

|

The jamb stock comes from solid 2" Mahogany

|

|

|

|

|

|

|

|

|

|

|

The solid brass, ball bearing hinges are mortised

into the jamb

|

Here is a view of the door in the jamb

|

Here the door is "standing" in the jamb

|

The finished door

|

|

|

|

|

|

|

|

Click on Any

|

Image to

Enlarge

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The door is bored for the oil-rubbed bronze

hardware

|

The bored holes have been oiled for the benefit of

the door

|

A little jig is left in the for hardware alignment

in the jamb

|

|

|

|

|

|

|

|

|

|

|

|