|

|

|

|

|

|

|

|

|

First the drawing ..... then it is transfer to to a

light cardboard, to be cut out and adhered to the glass for

cutting and grinding

|

There is 144 separate

pieces of glass in this one window

|

Joanne Fagerskog of FagerskogGlass.com is a master

stained glass worker

|

The templates are cut with a special scissors the removes

3/32" to compensate for the copper foil which will wrap each

piece of glass

|

|

|

Click on

ANY

|

Image to

Enlarge

|

|

|

|

|

|

|

|

|

|

|

Here is a piece that will be adhered to the glass

for cutting and grinding

|

pieces ready for cutting

|

Here are some of the deep green pieces for the leaves of

the Cypress trees

|

....... and some of the tree trunks

|

|

|

|

|

|

|

|

|

|

....... more pieces

|

|

then each piece is ground on a diamond wheel to the

exact rendering that has been designed

|

The small diameter diamond shaft is for tight inside

corners

|

|

|

Click on

ANY

|

Image to

Enlarge

|

|

|

|

|

|

|

|

|

|

|

Each piece is cut and fit to the drawing

|

Here are some of the pieces laid on the

drawing

|

When all the pieces are cut to size they will be

wrapped with copper foil

|

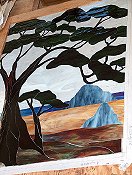

Here are all 144 pieces of glass which are cut out.

ground to shape, and fitted together ....... ready to be

wrapped with copper foil and then soldered

|

|

|

|

|

|

|

|

|

|

Then each piece of glass is hand wrapped with a

copper foil

|

....... that is wrapping all 144 pieces with a

copper border

|

then each piece is soldered to the piece next to

itself

|

and then the entire window is turned over and

soldered on the other side

|

|

|

|

|

|

|

|

|

|

A reinforcing "wire" is also soldered into large

windows to help make the window more rigid

|

The a sealing compound is rubbed into all of the

seams

|

...... ah yes ...... and the the glass wash

!

|

Some wax on the surface is the final step

|

|

|

Click on

ANY

|

Image to

Enlarge

|

|

|

|

|

|

|

|

|

|

|

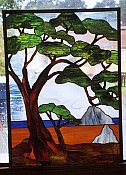

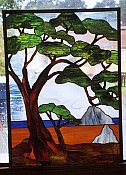

Here is the finished beautiful window ...... waiting

for installation

|

The glass is bedded and caulked with a special

siliconized latex that not only adheres to the leaded glass

.... but also to the wood

|

The excess caulked can be cleaned with water .....

and it takes many days to cure and it then turns clear and

is guaranteed for 50 years

|

The glass is set with redwood stops that are

attached with stainless steel fasteners .... and won't

"bleed out" rust over the years !!

|

|

|

|

|

|

|

|

|

|